The Whole arrangement of modern thermal power station consists of various components, namely

1. Coal and ash handling arrangement

2. Coal pulverization plant

3. Steam generating plant

4. Steam turbine

5. Alternator

6. Feed water

7. Cooling arrangements

8. Exciter

9. Instrumentation equipment

10. Chimney

1. Coal and ash handling arrangement

The main function of coal handling plant is to feed the coal to the boiler unit. The coal is Transported from the mines to the power station by road (or) rail (or) sea ways. The following are the various steps involved in coal handing are as follows:

a) Coal delivery

b) Unloading

c) Preparation

d) Transfer

e) Outdoor storage (dead storage)

f) Covered storage

g) In plant handling

h) Weighting and measuring

i) Feeding the coal into the furnace

a)

Coal delivery: The coal is delivered by ships (or) boats to power station suited near to

sea (or) river where as coal is supplied by rail (or) Tracks to the power

station which are situated away from sea (or) river. The transportation of coal

by trucks in used if the railway facilities are not available.

b) Unloading: The

type of unloading is mainly depends on how the coal is received at The thermal

power station.

i) If the coal

is received by the trucks then there is no need for Unloading equipment.

ii) If the

coal is received by the trucks then there is no need for unloading may

be done by car shakes, rotary car dampers, cranes, grab buckets and coal

accelerator.

c) preparation: The coal delivered to the power

stations is in the from of big lumps (or) size. Hence it needs to prepare

proper sizing of coal and it can be achieved by crushers, sizers, magnetic

separators and breakers.

d) Transfer : After preparation of coal it is then

transferred to the dead storage by means of the following systems.

i) Belt conveyors

ii) Grab bucket elevator

iii) Screen conveyors

iv) Skip hoists

v) Bucket elevators

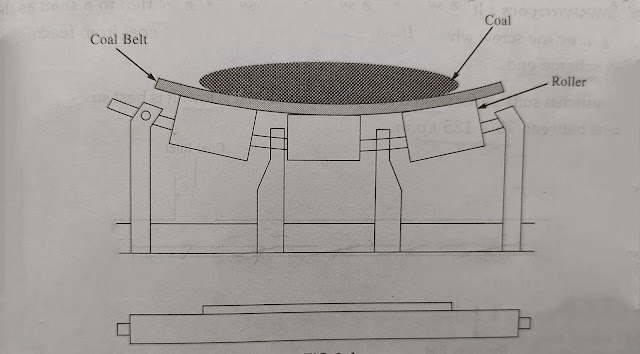

i) Belt conveyors : In this type of conveyors the belt is

made up of rubber (or) canvas. It consists of an endless belt moving over a pair

of end drums (rollers). The average speed of belt conveyors varies between

200-300 r.p.m.

Advantages:

· Its operation is smooth and clean.

· It requires less power as compared to other types of systems.

· Large quantity of coal can be discharged quickly and continuously.

· Material can be transported on 200 inclinations.

ii) Grab bucket

elevator: It lifts

and transfers coal on a single rail (or) track one point to the other. The coal

lifted by grab buckets is transferred to mover head bunker or storage.

The grab bucket conveyor can be used with crane (or)

tower as show fig below. The initial cost of this system is high but operation

cost is less. This system requires less power for operation and requires

minimum maintenance.

iii) Screw conveyors : It consists of an endless helicoids

screw fitted to a shaft as show in below fig. The screw while rotating in a

trough transfer the coal from feeding end to the discharge end.

This system is suitable suited for short distance. It

is best suited for operating speeds -between 75 – 125 r.p.m.

iv) Skip hoists: It consists of a vertical (or) inclined hoist way a bucket (or) a car guided by a frame and a cable for hoisting the bucket is held in up right position. The method is simple and compact for elevating coal (or) ash.

v) Bucket elevator: It consists of buckets fixed to a

chain which is moving on two wheels and is as shown in fig below. In this

method the coal is carried by the buckets from bottom and discharges at the top.

0 Comments